Ex-TSMC exec says the U.S. cannot stop China from improving its chip-making capabilities،

Remember in Jurrasic Park when Dr. Ian Malcolm (played magnificently by Jeff Goldblum) said that even if all the dinosaurs in the park were female, they would reproduce when “life finds its way.” And of course he was right. So what does this have to do with smartphones? Whatever restrictions and sanctions the

United States imposes on Huawei, the company seems to find a way.

From HarmonyOS to the Kirin 9000, Huawei has always found its way despite American sanctions

From HarmonyOS, which it developed to replace the Google Mobile Services version of Android after being placed on the entity list by the US Department of Commerce, until the creation of Huawei Mobile Services, the Chinese manufacturer has managed to surprising American lawmakers and officials by not rolling. and play dead.

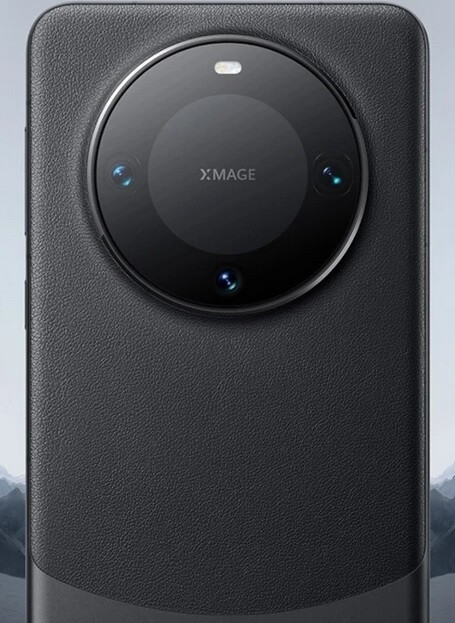

The Huawei Mate 60 Pro powered by the 7nm Kirin 9000s chipset

And even though Huawei is barred from getting 5G chips due to a U.S. export rule banning foundries that use U.S. technology from shipping to Huawei, the company stunned everyone in August announcing the Mate 60

series powered by its own 7nm 5G Kirin 9000s chipset. The application processor was produced by SMIC, China’s largest foundry, which used a deep ultraviolet (DUV) lithography machine and tools from other companies to build the chip.

SMIC is prohibited from purchasing the more advanced extreme ultraviolet (EUV) lithography machine, used to etch patterns on silicon wafers for the process node of 7nm and below. And although Huawei and SMIC are currently at the end of their technological capabilities with the Kirin 9000s chipset, former TSMC vice president Burn J. Lin says SMIC should be able to use the DUV machines already shipped by

ASML to produce 5nm chipsets. . According to

BloombergLin should know considering he was the person at TSMC who pushed the use of lithography machines that were a game-changer for the industry.

By using a lower process node, the bottom line is that smaller transistors are used, allowing chips to increase their transistor count; The more transistors a chip contains, the more powerful and/or energy efficient it is. The 7nm A13 Bionic used in 2019 on the

iPhone 11 series contained 8.5 billion transistors. The 3nm A17 Pro SoC that powers the iPhone 15 Pro and iPhone 15 Pro Max contains 19 billion transistors.

This month, the Biden administration closed some loopholes that could have allowed Huawei and SMIC access to some advanced U.S. equipment. ASML, the only company in the world manufacturing the EUV machine, recently reported that a former employee who stole ASML’s intellectual property related to chipmaking machines

I ended up working for Huawei.

Former TSMC exec says US can’t stop China from improving its chip technology

Lin says that in addition to making 5nm chips, Chinese foundries will work on using new materials and chip packaging to make more powerful chips. “It is simply not possible for the United States to completely prevent China from improving its chip technology,” Lin said. “What the United States should really do is focus on maintaining its leadership in chip design instead of trying to limit China’s progress, which is futile as the China is adopting a national strategy to boost its chip industry and hurt the global economy.”

Jeff Pu, a securities analyst in Haitong, estimates that Huawei could build 70 million smartphones equipped with its Kirin chips next year. China is the world’s largest smartphone market and the country was electrified and energized when Huawei announced the Mate 60 Pro, its first 5G phone since the release of the Mate 40 line in 2020.

Lin says the United States may be responsible for giving SMIC the ability to produce 5nm chips. He said export rules preventing TSMC from shipping 5G chips to Huawei, which at the time was the foundry’s second-largest customer after Apple, forced SMIC to work on improving its production capabilities. tip from 14nm to 7nm, and perhaps soon to 5nm. .