ASML hits back; Foundaries to use High-NA EUV machines for chipsets in 2025-26،

Dutch tech giant ASML delivered its first-ever high-NA EUV lithography tools to Intel in December 2024, which would allow Intel to make smaller chipsets with better performance. However, ASML has been criticized by analyst firms because it encourages customers to purchase expensive lithography tools, worth anywhere from $300 million to $400 million. So far, ASML CEO has spoken to Bits and chips in an interview explaining how its line of high-NA chipmaking tools are a logical, cost-effective solution available today.

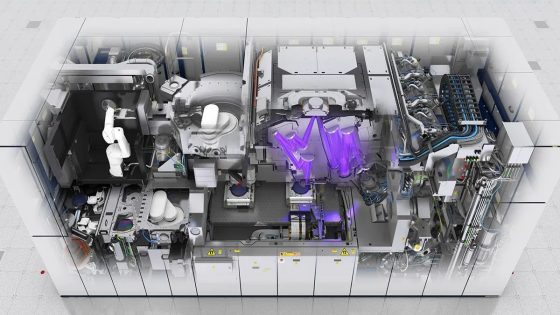

ASML is the EUV machine manufacturer that deals with giants such as TSMC and Intel developing and selling the tools used to make system-on-chips (SoCs). ASML's latest Twinscan EXE High-NA EUV lithography tools are the next generation EUV technology capable of creating sub-2nm chipsets. The machines typically cost between $300 million and $400 million per unit and use various technologies and features such as large dimensions and half the reticle size to process smaller chips while maintaining the yield rate.

Analyst firms have criticized ASML for selling expensive machines. ASML responded that they had underestimated the impact of using a next-generation lithography machine, including reduced cutting of double or even quadruple patterns, leading to higher risks of defects and lower rate of return. Intel's 10nm chipsets failed due to dual configuration and lack of robust EUV technology at the time.

For low-experience, low-NA tools currently in use, deploy methods such as dual modeling to distinguish circuits on tiny chips. This raises the question of why a chipmaker would buy an expensive high-NA EUV machine if the former can do its job properly. However, what this all boils down to is the increased risk of silicon wafers being overexposed to dual or even quadruple patterns, which could lead to defects and lower yield rates.

Note that the dual configuration is not that bad since TSMC used it on Apple A17 Pro and M3 chips made on the N3B process and they outperformed their predecessors. The risk, however, remains intact. Additionally, chips are expected to experience longer production times when exposed twice or more.

ASML has clearly stated that companies can weigh the pros and cons of upgrading to high-NA EUV machines before making a decision. Some tech giants will begin their research and development in 2024-25, followed by manufacturing in 2025-26, when EUV High-NA machines will acquire better cost/return on investment with their improved technologies and smaller manufacturing processes.

You can follow Smartprix on Twitter, Facebook, Instagram and Google News. Visit smartprix.com for the latest news, reviews and technical guides.