Gorilla Glass Armor: What is it and how is it made?،

Modern smartphones are fragile. there is no doubt. Just look at the booming market for smartphone cases. We've sort of done this ourselves, making these fancy electronic devices out of glass, but even though the backs of our smartphones can be made of anything, the screen needs a transparent material on it to …well, work. Enter Gorilla Glass! Most of you probably know the story. When Steve Jobs introduced the original iPhone in 2007, it featured a plastic screen that quickly scratched after a day of use. Mr Jobs contacted Corning, an American company specializing in glass and ceramics, and asked them to resolve the problem.

The first iPhone was quickly upgraded and shipped with “optical-grade glass to achieve a higher level of scratch resistance and optical clarity.” This glass was manufactured by Corning and, a year later, introduced as Gorilla Glass.

What people probably don't know is that Corning's first experiments with this type of glass began in the 1960s. In 2005, the company began developing a product light enough for use with electronics General public.

What is Gorilla Glass?

We all know about tempered glass. This type of glass is treated at high temperatures (600°C) to make it harder and more scratch resistant. Gorilla Glass is a little different. It uses chemical processes to change the composition of glass to make it harder and more resistant to damage.

But while tempering uses only high temperatures and rapid cooling, Gorilla Glass requires a more complex process called ion exchange.

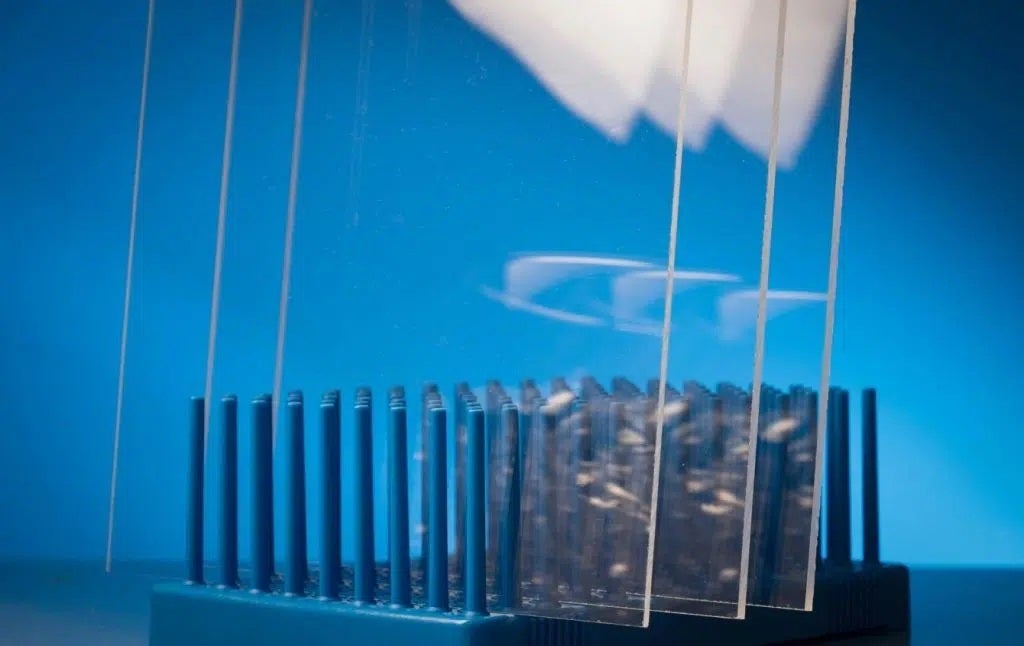

How is Gorilla Glass made?

- A sheet of ordinary glass is immersed in a bath of hot, molten potassium salt at temperatures around 400°C.

- The extreme heat causes the sodium ions to move out of the glass, while the potassium ions move into their place.

- Because the potassium ions are larger, they are pressed together, forming tighter bonds.

- The glass is removed from the salt bath and allowed to cool.

- As the glass cools, a stress layer forms, made up of these tightly packed potassium ions, now permanently frozen in the glass's crystal lattice.

- The potassium ion layer gives Gorilla Glass its scratch-resistant characteristics and durability.

Generations Gorilla Glass

Since the invention of Gorilla Glass in 2008, Corning has developed and perfected the technology, giving rise to different models of Gorilla Glass. The first generations used simple numbers and sometimes abbreviations such as SR+ and DX+, but as of 2020, Corning decided the names were better for the company and introduced the Gorilla Glass Victus.

Below is a complete table of all Gorilla Glass models and their features:

| Generation | 1 | 2 | 3 | 4 | 5 | SR+ | 6 | DX/DX+ | 3+ | Victus | Victory 2 | Armor |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Announcement | 2008 | 2012 | 2013 | 2014 | 2016 | 2016 | 2018 | 2018 | 2019 | 2020 | 2022 | 2024 |

| Density in g/cm3 | 2.42 | 2.39 | 2.42 | 2.43 | 2.4 | 2.4 | 2.41 | |||||

| Young's modulus to GPa | 71.5 | 70 | 65.8 | 77 | 77 | 77 | 79 | |||||

| Poison Ratio | 0.21 | 0.22 | 0.22 | 0.21 | 0.21 | 0.21 | 0.22 | |||||

| Shear modulus in GPa | 29.6 | 28.5 | 26 | 31.7 | 31.9 | 31.4 | 32.2 | |||||

| Vickers hardness (200 g load): unreinforced in kgf/mm2 | 534 | 555 | 489 | 559 | 611 | 590 | 595 | |||||

| Vickers hardness (200 g load): reinforced in kgf/mm2 | 649 | 653 | 596 | 608 | 678 | 651 | 670 | |||||

| Breaking strength in MPa m0.5 | 0.68 | 0.66 | 0.67 | 0.69 | 0.7 | 0.76 | 0.82 | |||||

| Thermal expansion coefficient (0–300 °C) in 10-7/K | 81.4 | 75.8 | 86.9 | 78.8 | 75.2 | 72.5 | 58.8 |

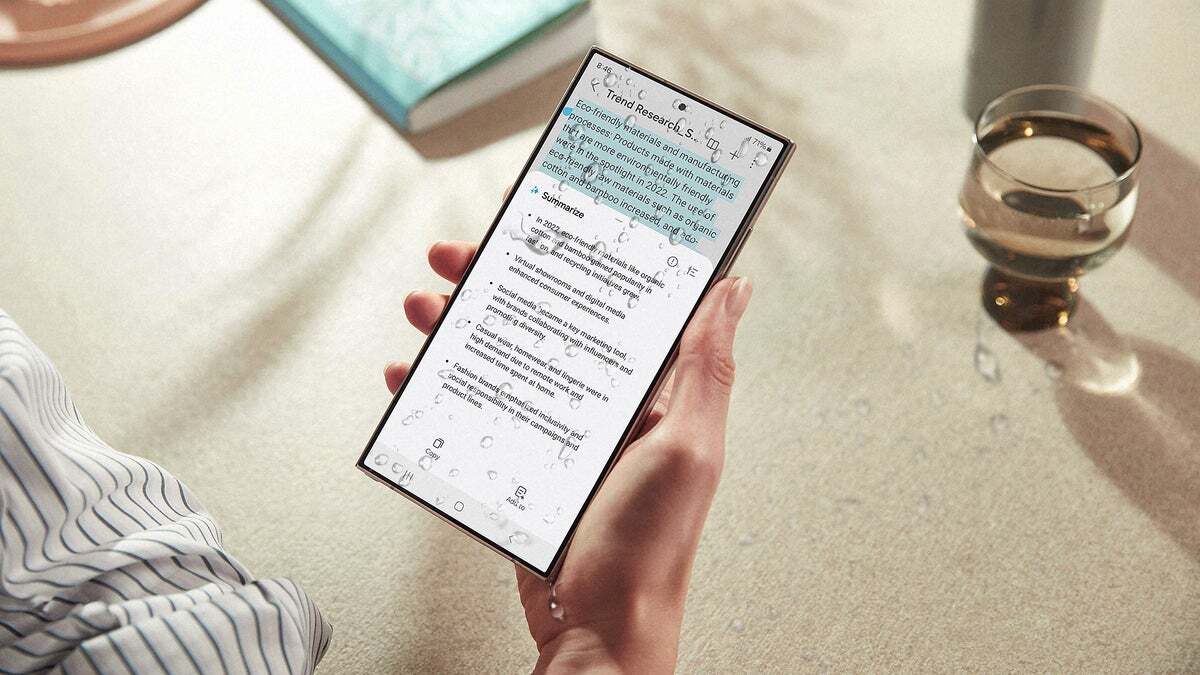

Gorilla Glass Armor

Another great advantage of the new generation is that it improves visual clarity by reducing reflectance by up to 75% compared to a standard glass surface, thus improving the readability of the display.

Is Gorilla Glass Armor much better?

Most of these claims are exaggerated or taken out of context. If you look at the table above you will see that the differences in hardness and breaking strength are not that great.

More practical approaches to testing different generations of Gorilla Glass have shown that scratch and break resistance is somewhat uniform across all generations. Sure, each new generation is slightly better, but the important word here is marginally.

That being said, sometimes small differences in these settings can mean the difference between a broken screen and an unharmed one. So it is of course better to have the latest version on your phone.

Gorilla Glass Applications

Gorilla Glass is used not only in smartphone screens, but also in the manufacture of car windshields, windows for residential and commercial buildings, laptop screens, monitors and televisions, as well as in many other applications requiring strong, scratch-resistant glass.

Alternatives to Gorilla Glass

The most popular is called Sapphire Crystal, and it is essentially a synthetic sapphire made in a laboratory under extreme heat and pressure. You're probably familiar with sapphire crystal because it's used on luxury watches and, lately, on some high-end smartwatch models.

Sapphire crystal has a hardness of 9 on the Moh scale and is almost scratch-proof. You will need a diamond or something at least as hard as a sapphire to make a dent or scratch in it. So where is my Corning sapphire crystal?

Making large sheets of sapphire crystal is difficult and expensive. There are smartphones with Sapphire Crystal coatings; Many Kyocera rugged models feature this material, but for the mainstream smartphone market it is considered too expensive and excessive. Sapphire crystal also transmits less light, which means darker displays.